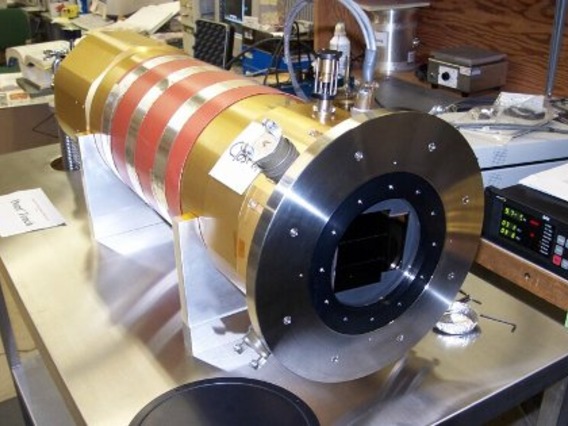

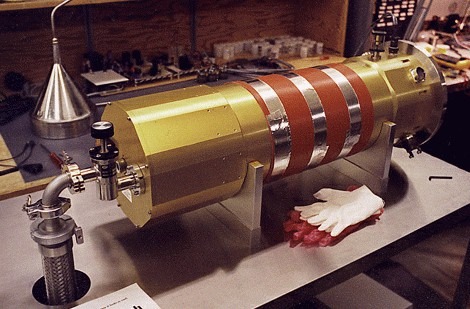

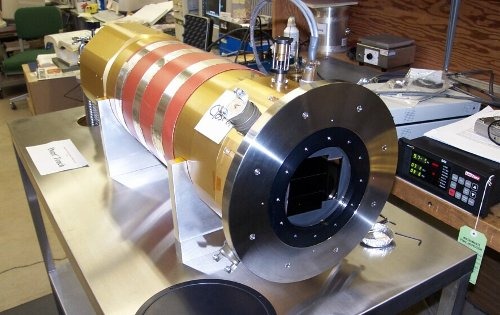

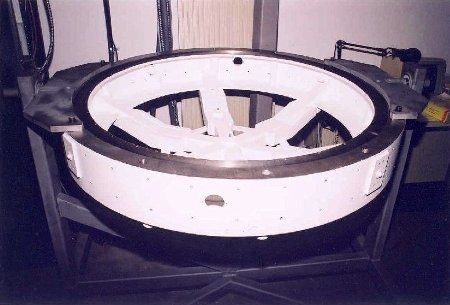

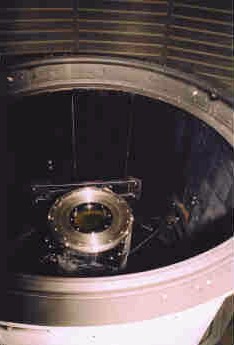

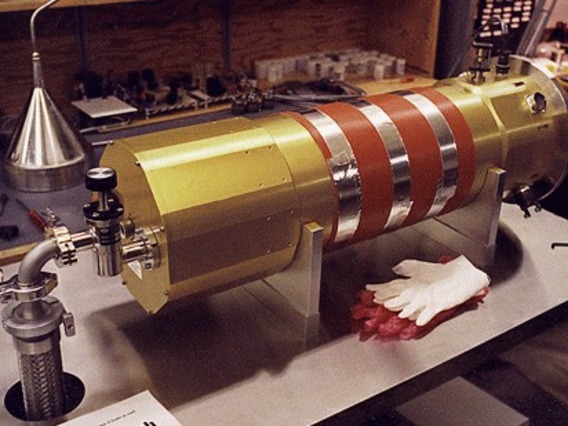

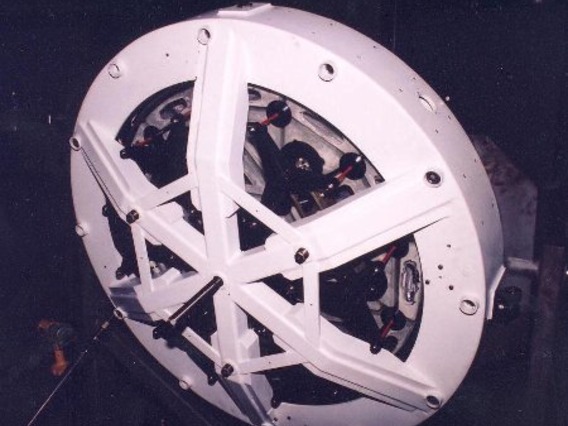

The new cryostat for the CCD mosaic before it was installed on the 0.9-meter telescope. (Photograph by Robert S. McMillan)

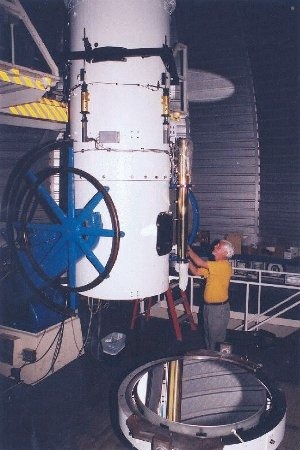

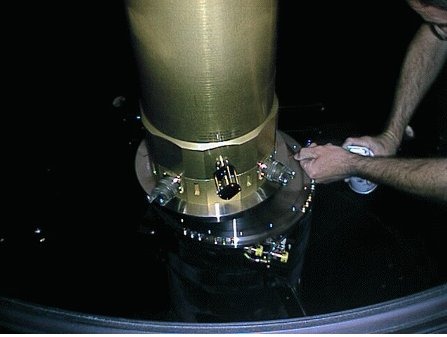

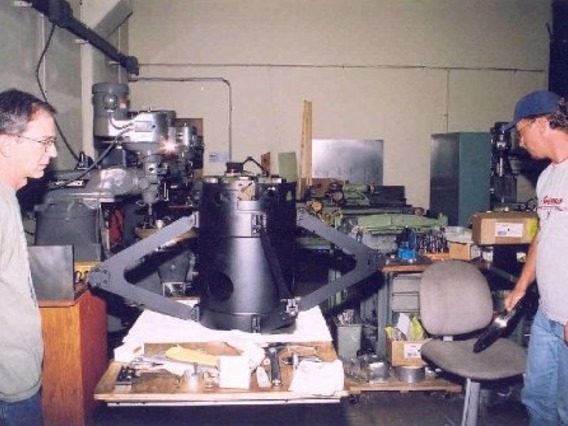

The instrument spider assembly. This holds and precisely positions the optical corrector as well as the camera cryostat containing the mosaic of 4 CCD imaging detectors. At left is SPACEWATCH® Chief Engineer, Marcus Perry, and at right is Instrument Maker, Bill Verts, of LPL. The large central cylinder has been covered with black "flock" cloth since the time of this photograph. (Photograph by Robert McMillan)

Back side of the new Wangsness 37 inch mirror blank which was designed to fit an 18 point support system. (Photograph by Joe Montani)

The Mosaic mirror arrived at our Lab from the coater on Sept. 24, 2002. This image depicts the mirror still in its wood air-freight crate; our form-fitting foam packing has been removed from around the edge of the mirror. The very highly reflecting overcoated Silver coating reflects more than 99.5% of incident light across our working bandpass, and the reflectivity peaks at 99.7-99.8% at 700 nm, the center of our bandpass. The lightweighted mirror weighs only 225 pounds (about 100 kg), or 35% the weight of a solid glass mirror of this size. Clear aperture is 36.75 inches (93.35 cm). Mike Williams, LPL Senior Staff Engineer, is seen near the mirror, and reflected in it. (Photograph by Robert McMillan)

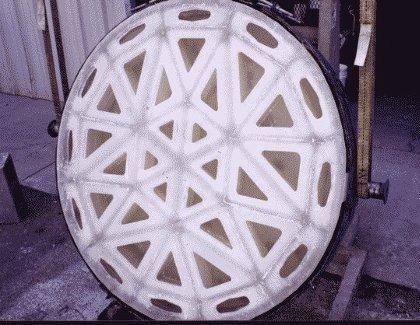

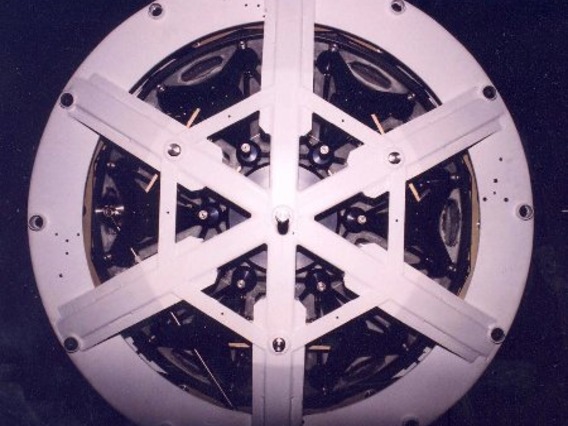

A view from the bottom of the mirror: the open triangular cells are visible (and oblong cells near the perimeter of the mirror). Through the inspection-polished bottom surface one may see the thickness of the Pyrex glass ribs between the open cells. (Photograph by Robert McMillan)

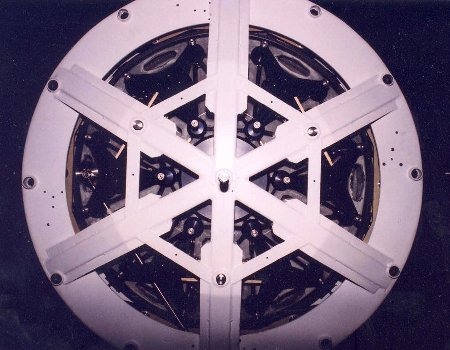

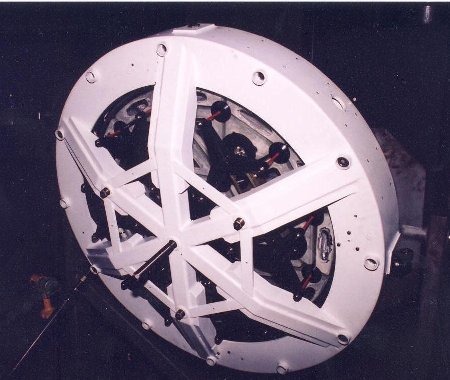

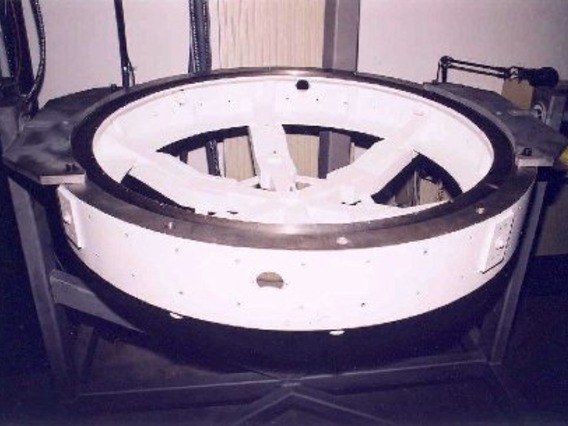

The new primary mirror cell, powder coated white. This cell has excellent ventilation, and will keep the new lightweighted telescope mirror very close to nighttime ambient air temperature. It is provided with an 18-point support system, and a novel radial support system designed by Mike Williams, LPL Senior Staff Engineer.(Photograph by Robert McMillan)

The mirror cell is shown here completed and assembled. The axial and radial support pads and flexure struts preserve the accuracy of the mirror figure while the mirror undergoes varying gravitational loading as the telescope points to different angles in the sky. The central lifting pad is seen fully extended: this lifts the mirror from the cell when cleaning or recoating is needed. (Photograph by Robert McMillan)

A view from the observing floor of the cast-iron center section of tubework to which attach the top tube section and mirror cell. Note the wood-circle grappling handle which was once used for positioning the telescope in Declination by hand (but not since the move to Kitt Peak in 1962, by which time both axes' motions were electrically motorized). The elevator platform is seen at the top. (Photograph by Robert McMillan)

A vertigo-inducing view downwards from the "elevator" Newtonian platform of the 36-inch telescope dome towards the observing floor, showing the telescope with its top tube section removed, and mirror cell removed. We see the very heavy and strong cast-iron rib structure of the central tube section which is connected to (and turns with) the declination axle, made around 1920 by Warner and Swasey, in Cleveland, Ohio. Such a view has not been seen in forty years, when the telescope was moved from Tucson to its present site atop Kitt Peak. (Photograph by Robert McMillan)

The original 80-year-old 7 foot-long top tube section of the telescope, at the LPL Machine Shop, just back from powder-coating (that's the SPACEWATCH® Webmaster, Mike Read, toasting the occasion). A beautiful and durable hard white finish has been baked onto the outer surface of the tube, and a flat black finish on the inside of the tube. The powder coatings will protect the metal for decades without need for re-finishing, and they lend fine aesthetics. We have also now lined the inside of the tube with a very effective light-absorbing "flock" cloth fabric, to minimize scattered light, and possibly to allow us to observe closer to the moon (if necessary) than we have ever easily done. (Photograph by Robert McMillan)

The powder-coated tube standing upright in the LPL Machine Shop. The square black frame which will support the instrument spider and allow for optical collimation adjustments as well as focus motions is seen about 2/5 of the way down from the top of the tube. (Photograph by Robert McMillan)

A study in symmetry: the lightweight Mosaic mirror seen from its back suface, fully installed in the mirror cell and supported by the axial and radial flotation system that the cell provides. (Photograph by Robert McMillan)

The mirror is seen here installed and safely restrained in the cell. The cell is tilted to a large angle from the vertical (nearly so much that the mirror axis is pointed almost horizontally). The mobile handling fixture enables tests and motions of this kind, as well as easy and secure installation and de-mounting of the mirror and cell on the telescope. (Photograph by Robert McMillan)

Senior Research Specialist Joe Montani examines the recently reassembled telescope and the carefully restored refractor finder scope built by Alvan Clark and Sons in 1888. ( This fine telescope was removed from the 0.9-m telescope in 2013 March and handed over to Steward Observatory for display at their main campus location.) The new 0.9-meter primary mirror in its new cell is visible in the foreground. The linear actuators on the sides of the telescope control focus and tilt of the CCD. (Photograph by Robert McMillan)

View of filtered light transmitted through the schott OG-515 filter and the field corrector lenses, seen from under the telescope before the mirror was installed. The inside surface of the telescope tube is coated with black flocking. (Photograph by Robert McMillan)

View of the field corrector lenses and filter from above, before installation of the CCD. (Photograph by Robert McMillan)

2002 October 9: Installation of the new primary mirror and its cell onto SPACEWATCH® 0.9-meter telescope. (Photograph by Terry Bressi)

2002 October 9: Installation of the new primary mirror and its cell onto SPACEWATCH® 0.9-meter telescope. (Photograph by Terry Bressi)

Installation of the new primary mirror and cell on 2002 Oct. 9. Left to right are Brett Lawrie, Joe Montani (hidden), Bill Verts and Mike Williams. (Photograph by Robert McMillan)

The new mirror cell is seen attached to the end of the telescope, on Kitt Peak. One can see here the great amount of free-air ventilation that the Mosaic mirror will enjoy; this will preserve image quality and help the Mosaic telescope to make faint detections. (Photograph by Terry Bressi)

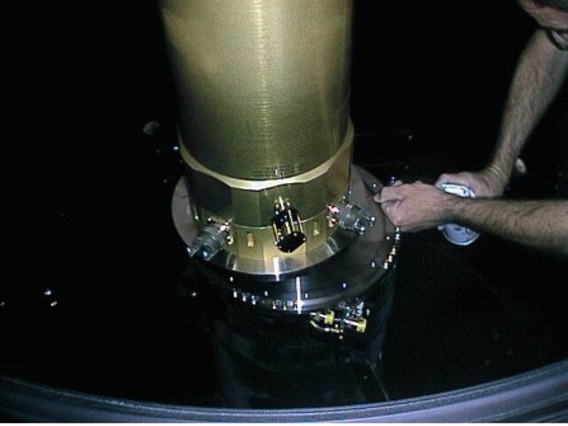

Mike Williams of the LPL Machine Shop installs a small format CCD at the corrected prime focus for initial determination of focus on 2002 Oct. 9. (Photograph by Robert McMillan)

2002 October 14: Cryostat containing the mosaic of CCDs, rigged for hoisting onto the top end of the telescope. Brett Lawrie on the left, Mike Williams behind the cryostat, Bill Verts in the background on the right, and Marcus Perry making adjustments. (Photograph by Terry Bressi)

Mosaic of CCDs being lowered onto the focal position on 2002 October 14. (Photograph by Terry Bressi)

2002 October 14: Final installation of the mosaic of CCDs onto the focal position of the SPACEWATCH® 0.9-meter telescope. v

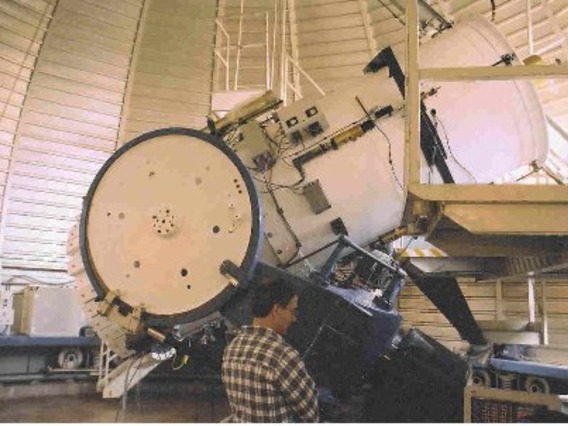

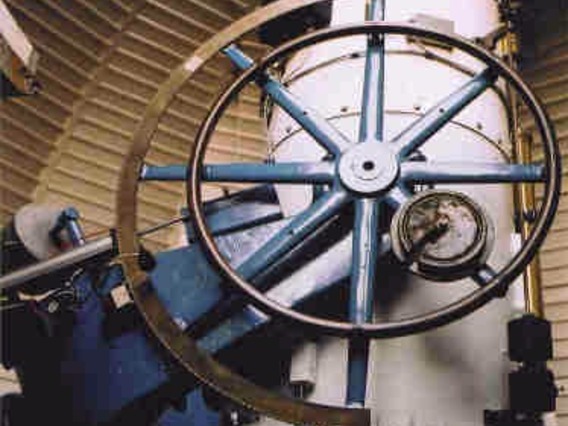

2002 October 21 - SPACEWATCH® 0.9-meter telescope in new prime focus mode, viewed from the west. The square frame holds the center spider. On of four linear actuators for focus, tip, and tilt is at the upper center of the tube. The large declination drive gear and its motorized worm drive is in the foreground below. (Photograph by Robert McMillan)

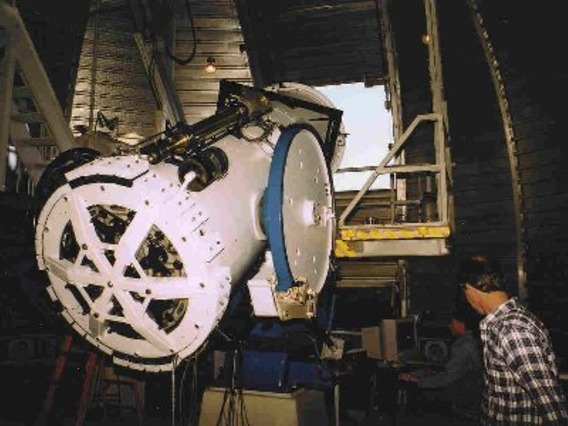

2002 October 21 - SPACEWATCH® 0.9-meter telescope in new optical configuration undergoing engineering trials. Chief Engineer M. L. Perry in the foreground (Photograph by Robert McMillan)

2002 October 21 - SPACEWATCH® 0.9-meter telescope in new optical configuration undergoing engineering trials. Chief Engineer M. L. Perry and Staff Engineer T. H. Bressi in the background. (Photograph by Robert McMillan)

Andrew Tubbiolo and Joe Montani prepare to fill the cryostat through the funnel placed in the end of the unit. (Photograph by Robert McMillan)

2002 October 21 - A. F. Tubbiolo fills the mosaic cryostat with liquid nitrogen at the prime focus of the SPACEWATCH® 0.9-meter telescope while J. L. Montani looks on. (Photograph by Robert McMillan)

2002 October 21 - One of the best views of the recently restored antique brass refractor finder scope built by Alvan Clark and Sons (http://www.lpl.arizona.edu/~jmontani/clark.html) in 1888. Engineer T. H. Bressi works at the telescope drive console. (Photograph by Robert McMillan)

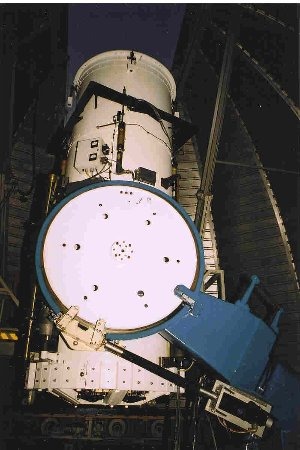

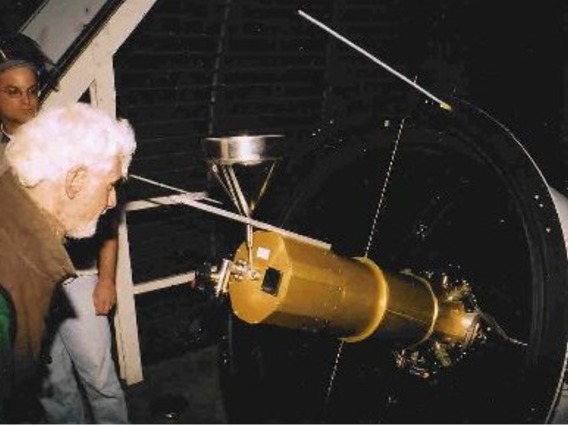

2002 October 21 - The front top end of the SPACEWATCH® 0.9-meter telescope, showing the newly installed cryostat with the mosaic of CCDs. Four wires run from the gold-colored cylindrical cryostat to counter balancing weights that tension the wires and prevent the cryostat from sagging as the telescope points lower in the sky. The large black box at the lower right houses the electronics that control and read the four CCDs. The square black frame around the telescope tube braces the spider inside the tube that holds the corrector lenses and the base of the cryostat. (Photograph by Robert McMillan)

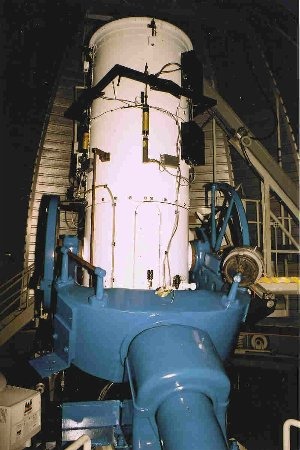

The SPACEWATCH® 0.9-meter telescope reconfigured with new optics as of 2002 October 21. Note the shorter tube and the framework near the top to which the new central support spider is attached. The first detection of an asteroid (PHA 2002 TD66) was made with the mosaic of CCDs on October 23. (Photograph by Robert McMillan)